Laboratory

Hands-on experiments in thermal systems, controls, and instrumentation. Tools used include LabVIEW, MATLAB/Simulink, and ANSYS.

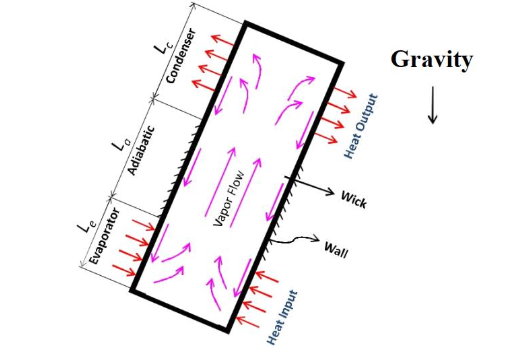

Heat Pipe Experiment

Characterized passive thermal transport with thermocouples and LabVIEW DAQ; benchmarked against solid conduction and quantified uncertainty.

Project Details

Evaporator/Condenser instrumentation and steady-state logging in LabVIEW; calibration and RSS uncertainty; comparison against copper rod to illustrate effective conductivity gains.

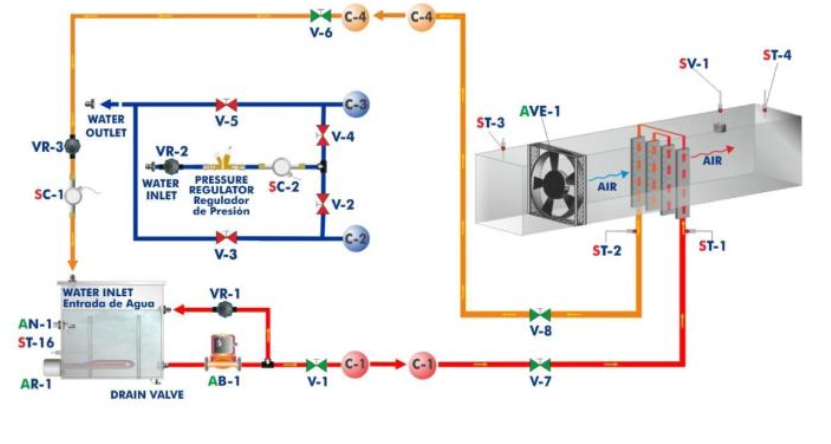

Heat Exchanger Performance

Evaluated effectiveness–NTU and UA; compared measured trends with ANSYS Fluent predictions for sizing and performance.

Project Details

Computed ε–NTU/UA and capacity ratio; validated correlations and CFD; discussed pressure-drop trade-offs and design implications for target outlet temperatures.

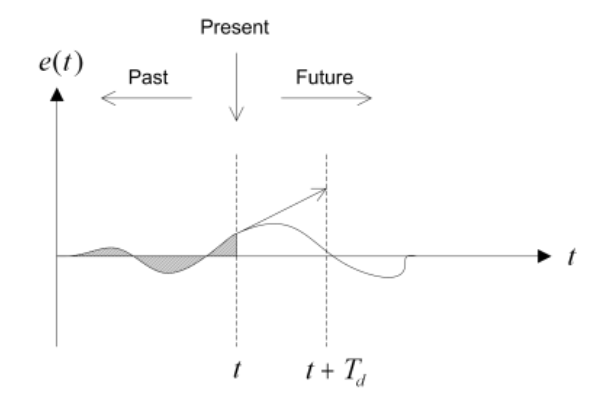

PID Control of DC Motors

Tuned P/PI/PID in MATLAB/Simulink to balance rise time, overshoot, and steady-state error; linked simulation to benchtop response.

Project Details

Time-constant estimation and first-order approximation near the operating point; transient metrics vs design targets; robustness considerations for automated manufacturing systems.

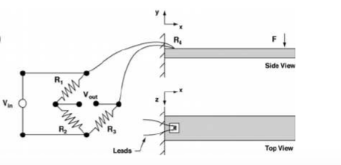

Strain Gauge Beam Deflection

Measured strain on a cantilever using bonded gauges and LabVIEW DAQ; validated Young’s modulus against ANSYS structural analysis.

Project Details

Gauge calibration, repeated trials, and drift checks; curvature–moment regression; FEA cross-check of deflection/stress to support modulus estimate.